Infrared Thermography and Charge Exchange Diagnostics Division

Introduction to Infrared Thermography and imager

Infrared Thermography is the science of acquisition and analysis of thermal information by using non contact thermal imaging devices. Visible photograph depicts spatial distribution of light or colour intensity similarly “thermo-graph” depicts spatial distribution of temperature values.

Plasma diagnostics based on the Infrared Thermography technique

Infrared Thermography emerged as an important tool in the field of high temperature plasma diagnostics and fusion research since it has the advantage of real time imaging of the surface temperature of an object, remotely. Infrared imaging has multiple applications. It can be used for surface temperature measurement of Plasma Facing Components (PFCs) for studying the plasma wall interaction and also for health and safety monitoring of the PFCs. It is also used for in-vessel inspection during plasma discharges and heat load estimation on the PFCs, whereby establishing power balance between input and the exhaust power from the plasma. Another important application of Infrared imaging technique is for estimation of particle flux and radiation flux emitted from the confined plasma in broad wavelength range by using an Infrared Imaging Video Bolometer. Infrared imaging also finds an important application for studying the synchrotron radiation emitted by “Runaway Electrons” accelerated by toroidal electric field. The radiation emitted by such electrons falls in IR range which can be detected by Infrared imaging & various parameters of “Runaway Electrons” can hence be derived. Infrared imaging diagnostics are less susceptible to the electro-magnetic and nuclear radiation induced noises, provided suitable shielding techniques are used. Considering all the merits of Infrared imaging diagnostics it can be concluded that it is an inevitable diagnostic for fusion research. Different Infrared imaging diagnostics are deployed on the ADITYA and SST-1 tokamaks. Brief disruption of each diagnostics is given below.

Infrared Thermography (IRT) of Plasma Facing Components

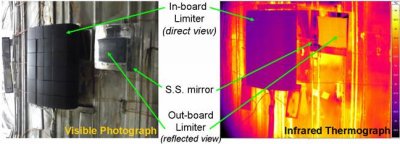

Infrared Thermography (IRT) of Plasma Facing Components (PFCs, namely Limiter, Divertor etc.) is one of the most essential tools to investigate interaction of plasma with PFCs as it has an advantage of real time monitoring of the surface temperatures remotely with wide field of view (FOV). There is a possibility of damage to the PFC tiles due to intense localized heating load under various conditions and also the particles ejected from the tiles can affect plasma boundary condition. For this reason, infrared thermographic measurement has become important for monitoring surface temperature and estimating thermal loads on inboard and out board limiter tiles. Infrared imaging system provides information on excessive temperature of component or power deposition profile on the PFCs.

Visible photograph (left) shows in-board limiter and out-board limiter (mirror reflection) of the SST-1 tokamak from IR-camera view-port. Corresponding IR-thermograph shows in-board limiter tiles and out-boards limiter tiles covered in the same field of view of the IR-camera

An IRT system is deployed on the ADITYA and SST-1 tokamak. The system has wide field of view which covers inboard limiter in direct view and outboard limiter in reflected view using stainless steel mirror mounted on the inboard side. Presently this IRT system has measurement role for health monitoring of the limiter tiles and physics studies.

Infrared Imaging Video Bolometer

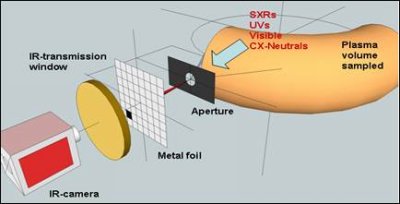

Infrared Imaging Video Bolometer (IRVB) is one of the modern plasma diagnostic which provides the measurement of the temporally resolved two & three dimensional (2-D / 3-D) power profile radiated from the plasma devices. It utilizes free standing ultra thin large area metal foil, which absorbs radiated power from high temperature magnetically confined plasma through pinhole camera geometry in wide spectral range (SXR to UV). This absorbed power alters the temperature profile on the foil area which is optically (by infrared radiation) imaged and measured by the Infrared Camera seating out side the vacuum vessel through Infrared Transmitting vacuum view port. Using heat diffusion analysis of 2-D temperature profile, total radiated power profile from plasma can be determined. Since the IRVB is optically transmits the signals (Infrared Radiation) it is immune to EM noise and also can work under reactor relevant conditions, hence it is more suitable for the steady state high temperature plasma devices and future fusion devices.

The techniques is being first time utilize for the medium size tokamak the ADITYA. IRVB system is designed, developed and installed on the SST-1 tokamak also.

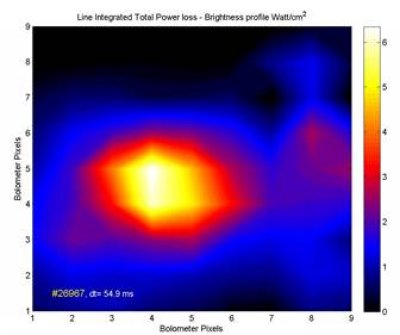

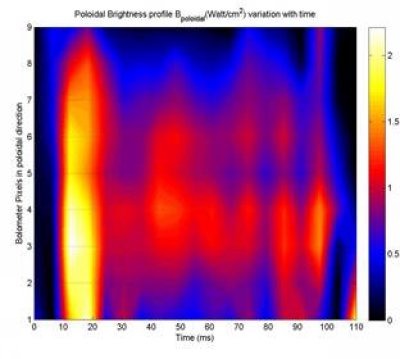

Plasma power brightness profile from the ADITYA IRVB-system (left) and temporal evolution of poloidal brightness profile (vertical array, x=1 & y=1:9) for the plasma discharge #26766 (right)

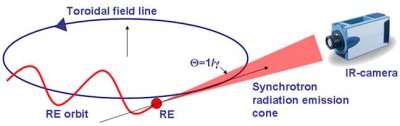

Detection of synchrotron radiation emitted by “Runaway Electrons” using IR-Camera

Runaway Electrons (REs) generation and energy dynamics is a major concern for the present day tokamaks. This may occur during different phases of the plasma discharge like start-up, flat-top, ramp-down, failed breakdown or during disruptions. Production of REs depends on toroidal electrical filed and plasma density. In large tokamaks, REs can be confined for long durations hence, they gain energy up to few tens of MeVs and with significant fraction of discharge plasma current. It is essential to estimate RE parameters, namely: density, energy, energy distribution function and pitch angle etc. since they can cause substantial damage to first wall and other in-vessel components of a tokamak if they are deconfined.

The main reasons for investigating REs are: (a) Machine protection since deconfined REs can cause severe damage to the first wall, (b) Basic Control to prevent such mishaps, (c) Physics studies since REs can act like test particles to investigate turbulent transport due to magnetic or electric fluctuations.

Conventional runaway diagnostics measures those runaways that are no longer confined (Hard X-Ray monitor). Soft X-Ray-array and Fast Electron Bremsstraulangh -array has limitation to detect high energy REs (Energy> 20 MeV). This demands a new diagnostic technique which detects REs when they are still confined inside the plasma and should detect REs with high energy also.

It is well known that accelerated charge particles emit electromagnetic radiation. For relativistic electrons in a magnetic field, this emission is called synchrotron radiation. For typical tokamak parameters, the synchrotron radiation spectrum peak falls in the infrared band. The synchrotron radiation measurement with Infrared imaging camera provides a tool to detect REs when they are still confined within the plasma. Detection of synchrotron radiation and analysis provides RE parameters namely, Pitch angle, beam radius, energy and current.

CHARGE EXCHANGE DIAGNOSTICS

Introduction: The Charge Exchange system is installed at ADITYA tokamak (radial port no. 10) and has successfully been operated during the plasma discharges to measure the core ion temperature during the evolution of ohmic plasma [1].

Charge Exchange Diagnostics is also to be deployed at SST-1 for measuring the core ion temperature of the plasma. The charge exchange system for SST-1 has been designed, fabricated and is in the process to be integrated with SST-1. At present in both the tokomaks, Aditya and SST-1, the measurement of core ion temperature is based on the passive mode of charge exchange diagnostics which uses the neutral particle analyzer [NPA] with the electrostatic parallel plate configuration to resolve the different energy components in the neutral beam which comes out of the confined plasma. After the successful integration and operation with the SST-1, the diagnostics has to be upgraded for the active method of ion temperature measurements using the diagnostics neutral beam injection into the plasma.

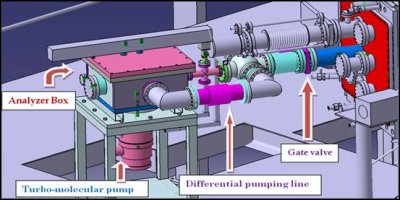

System Description: The diagnostics system for SST-1 comprises of a drift tube which connects with the SST-1 radial port no. 15 using an isolation pneumatic gate valve and a DC break. On the other end this drift tube is connected with a 35 CF cross chamber (stripping cell of 200mm length). This cell is further connected to the Analyzer box (460mm × 460mm × 275mm, outer dimensions) which consists of parallel plate assembly (a set of plates) where a retarding electrostatic field is applied, on the ions emerging out of the stripping cell, between the top (positively biased) and the bottom plate (grounded). This box is evacuated using a 1200 ltrs/sec TMP through the port available at the rear plate of the Analyzer box. The whole assembly is evacuated with the same pump using the differential line. The analyzer box is placed over a support structure (~ 500mm×500mm×1460mm) which is capable of bearing the load of ~200 kg.

Figure-1: layout of the CXD system for SST-1

Figure2: CXD System layouts with SST-1 at radial port no 15

The CXD system at Aditya:

Figure3: CXD system at Aditya