Large Scale Cryogenic Plant and Cryosystem Division

Introduction

This division was created in Apr-2012 mainly to develop kW class helium refrigerator-cum-liquefier (HRL) and peripheral cryo-components required for large scale R&D programes like, fusion tokamaks and accelerators. In the 12th 5-year plan, this division has taken up a project for development of helium plant of 2 kW cooling capacity at 4.5 K. It will also have provision to produce cooling capacity at temperature lower than 4 K. This HRL involves R&D for many cryogenic components along with bringing up industry infrastructure in the country. Presently this division is actively engaged with many design and analysis activities towards achieving this HRL project.

Design and Analysis

Presently following design and analysis activities are going on:

- Plate-fin heat exchangers(includes multi-fluid, multi-stream (more than 2 streams) and two-phase flow) required for helium rerigerator/liquefier (HRL).

- Process analysis of thermodynamic cycle of HRL.

- Helium gas purification systems at different temperature levels: room temperature (~300 K), ~80 K and ~20 K.

- Cryogenic ejector pump.

- Compressor and oil removal system of HRL.

- Helium turbo-expanders operating at temperature below 50 K.

- Design of HRL cold box

Prototype developments

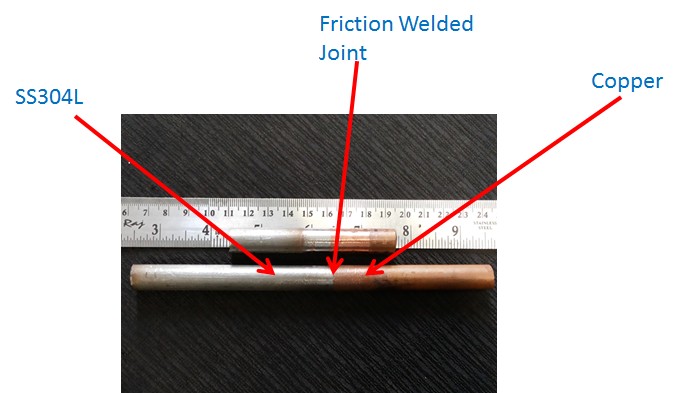

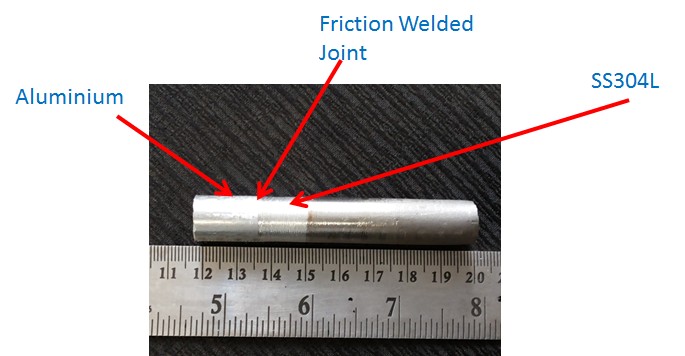

Development of Copper to SS304L and Aluminium to SS304L friction welded joint for Cryogenic application:

Recently using lathe machine friction welding have been performed and leak tests after thermal shocks at liquid nitrogen temperature showed significantly low leak rate of less than 5x10-9 mbar.l/s. This was done for ½ inch size tube. The tests for 1 inch size friction welded tubes are in process

Prototype developments

Development of Copper to SS304L and Aluminium to SS304L friction welded joint for Cryogenic application: