Data Acquisition

Data Acquisition

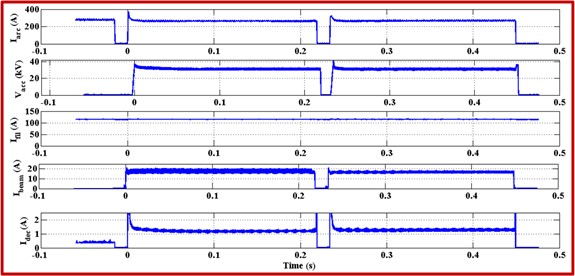

Electrical parameters, like plasma arc current (I arc), acceleration voltage (Vacc), filament current (Ifil), beam current (I beam), and deceleration current (Idec) are required for optimization of beam extraction. In addition to these, gas feed rate and vessel pressure on same time scale present meaningful information for analysis purpose. As mentioned above, few of these parameters are measured at acceleration potential (up to 55kV) and rests are at ground potential.

USB based DAQ

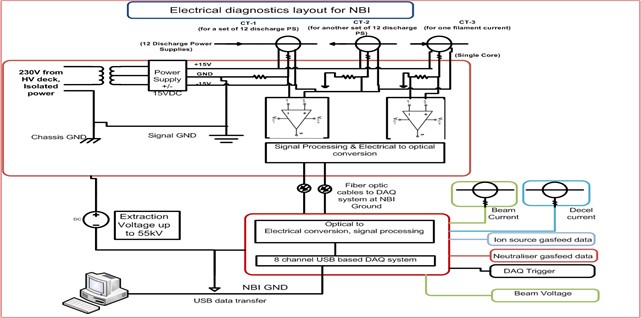

A dedicated signal conditioning and data acquisition system was developed in house for processing of these signals at different potentials and finally acquiring them on single time scale. Hall probe based current transducers (CT) are used to measure Iarc, Ifil, Ibeam and Idec. CTs for deceleration current and beam current are mounted of ground potential while arc current and filament current CTs are mounted on acceleration potential. Front end electronics of Iarc, Ifil is also kept floated to same potential. Processed signal is converted to optical signal before merging to signal processing system at ground potential. Above Figure shows a block diagram of electrical diagnostics.

Measurement of arc current, Iarc, acceleration voltage, Vacc, filament current, Ifil, beam current, Ibeam, and deceleration current, Idec.

Thermal diagnostics

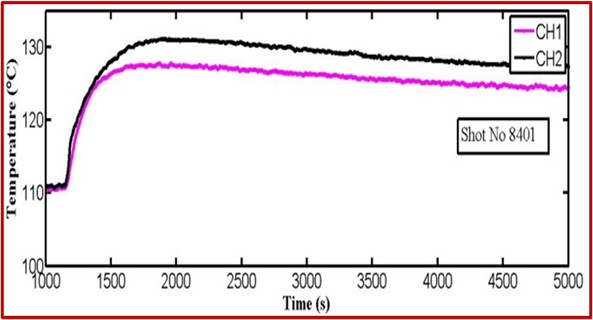

Beam power density profile and beam divergence are estimated by thermal diagnostics. K type thermocouples are mounted at different locations on beam line components. Temperature of these components rises due to passing or dumping of beam to these components. By measuring this change in temperature, beam power profile and divergence can be estimated. Hot junction is covered by shield to avoid any breakage during mounting to vessel components. Hot junction has direct contact with the shield so fast thermal response can be recorded.

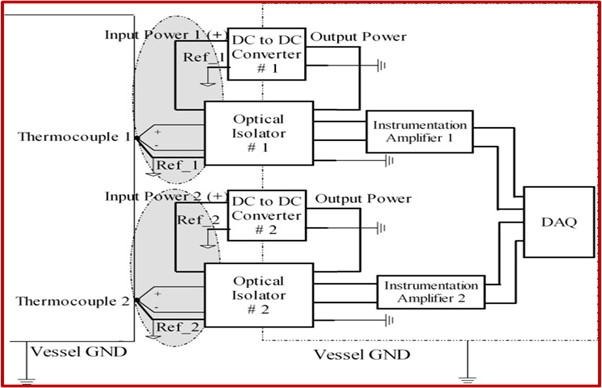

Beam operation involves very fast (<5µs) turn off and on of high voltage power supply (up to 55kV). This causes high dV/dt and significantly contributes in noise pick up by electronic components nearby. Thermocouples are inherently very sensitive signal, need additional care of electromagnetic interference immunity in such case. Below Figure presents a block diagram of in house developed signal processing system capable in producing noise free data.

Thermocouple signal processing scheme for calorimeter

Thermocouple signal processing & DAQ system

Front end electronics of above scheme employed an optical isolator to isolate thermocouple with back end electronics. In this way, it makes every thermocouple independent to each other and removes the possibility of ground loop formation. A passive RFI filter removes common mode noise.