Industrial & Societal Application

Plasma Based Technologies & Applications

IPR has a long-standing, focused programme for developing plasma technologies for a variety of societal applications, such as waste management & environment, medical/health, agriculture, textile, industrial, space, defence etc. Considering the immense potential of plasma technologies in society & industry, IPR had setup a dedicated centre named "Facilitation Centre for Industrial Plasma Technologies" in 1997. This centre interacts closely with industries and user organizations to develop and commercialize plasma technologies in project mode. These are time-bound projects with clear deliverables involving partnerships with a variety of end-users including industry and other research organizations. Technology has also been transferred to industry in several areas. A Brief details have been given below

For more details visit FCIPT>>

Plasma Surface Engineering Applications

Plasma is a highly active state of matter (4th state) and interacts in different ways with the solid surfaces (1st state of matter). Plasma may physically or chemically interact with the material surface thereby resulting in specific surface properties. This property of plasma can be utilized for various applications such as tribology, environmental remediation (catalysis), biomedical & health sector, agriculture etc. IPR has been exploiting plasmas for surface modification for various industrial processes and products through its Facilitation Centre for Industrial Plasma Technologies. FCIPT also runs a 'plasma nitriding' jobshop wherein industry can come with their surface hardening/nitriding jobs and get the treatment done on chargeable basis. This is done to demonstrate technology on an industrial scale. A few highlights are discussed below.

Recent Developments:

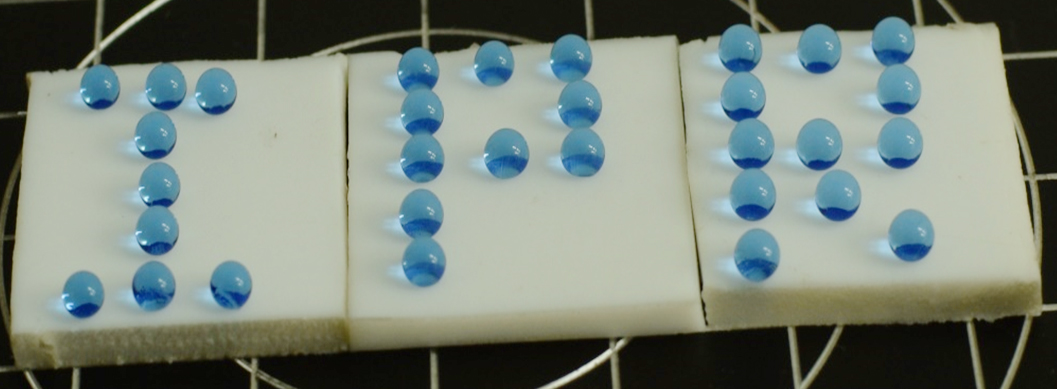

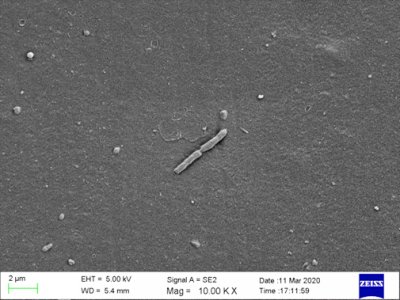

Water Repellent Super hydrophobic PTFE Surface Produced by Low Energy Ion Beam Irradiation : Super hydro-phobic surfaces are of great interest due to their superior waterrepellent applications, such as self-cleaning, anti-scratch, anti-icing, anti-corrosion and fog harvesting. Super hydro-phobicity is achieved by having a large contact angle (θ > 150°) with low surface energy. Surface properties are modified either by surface structuring or by changing surface chemistry. Teflon and Teflon-like coatings have several ap-plications in automobiles, non-stick cookware, and medical applications due to high heat resistance, excellent electrical insulation and biocompatibility. As PTFE is hydrophobic in nature, many investigations have been carried out to alter its wettability by modifying the surface structures. In our recently published study in Nature Scientific Report, we have found remarkable changes in wettability (increase in hydrophobic-ity) of PTFE after just a few seconds of Ar+ ion beam irradiation at energies as low as 300 eV. We have also found that PTFE surface become superhydrophobic under lower energy (300 eV-800 eV) Ar+ ion beam irradiation. Also, with the help of oblique incidence irradiation, the surface can become superhydrophobic at much lower fluences and energies without any additional gas and high energy ion beams. From a technological view point, this technique would be helpful for developing superhydrophobic bulk PTFE sheets with small duration irradiation; also, parts of the surface can be made superhydrophobic by using masking or ion beam writing.

Photograph of the Hyprophobic PTFE surface produced

In-vitro and In-vivo studies using Plasma Jet for oral cancer cells: IPR is collaborating with ACTREC to study the interaction of plasma jet with oral cancer cells. Initially, the plasma jet parameters were optimized for in-vitro condition in terms of voltage and duration of treatments. In this study, plasma jet treatment was done on oral cancer, breast cancer and HEK293 cell lines using biological assays. On the basis of the in-vitro findings, preliminary in-vivo studies were initiated on tumors generated in hamster buccal pouch (HBP) model. Further studies to understand the mechanism of inter-action are in progress.

Development of multilayer (TiN, TiAlN) coating on zirconi-um alloy tube: We are exploring the possibility of developing multilayer coatings of TiN and TiAlN coatings on zirconium based alloy tubes, which are used in nuclear power reactors. The coatings have been performed by cylindrical magnetron sputtering technique by modifying an existing system. Water cooled Titanium (Ti) and Aluminium (Al) cylindrical targets along with substrate rotation assembly were incorporated in the vacuum system. Preliminary experiments for the deposition of TiN and TiAlN as individual and multilayers were carried out. The process has been optimized for the deposition of TiN and TiAlN on the outer side of cylindrical stainless steel tubes. Similar coatings on zirconium alloy tubes will be developed and corrosion studies will be performed in the future.

Atmospheric Plasma Applications

Atmospheric pressure plasmas range from room temperature to high temperature depending on the power source configuration. The low temperature atmospheric pressure plasmas can be used for surface modification of materials while the bulk remains unaltered. At the same time, high temperature/thermal plasmas are used for bulk modification/smelting/melting applications. IPR has developed a number of processes and products using atmospheric pressure plasma for different applications at the Facilitation Centre for Industrial Plasma Technologies. A few applications of atmospheric pressure plasma are discussed below.

Recent Developments:

Development and supply of inline atmospheric pressure air plasma system for surface modification of HDPE film in Geo-membrane application: An atmospheric pressure air plasma system for the inline surface modification of HDPE (High Density Polyethylene) film has been developed by APD (Atmospheric Pressure Plasma Division), IPR and commissioned at CIPET (Central Institute for Plastic and Engineering), Ahmedabad in March 2020. This system comprises of 6 pairs of electrodes and generates a uniform glow discharge plasma in air over a width of 1.5 meter. The objective of this project is to develop a Geo-membrane with improved characteristics of strength and leaching. The plasma surface modification of HDPE film induces nano-scale surface roughness and increases its surface energy, which in turn can improve adhesion among different layers of HDPE used in Geomembrane. Detailed experiments for developing Geo-membrane from plasma modified HDPE films will be conducted by CIPET.

Air-plasma treatment system installed at CIPET Air-plasma treatment system installed at CIPET |  Ion-Acoustic Wave and Langmuir Probe System installed at UM-DAE CEBS

|

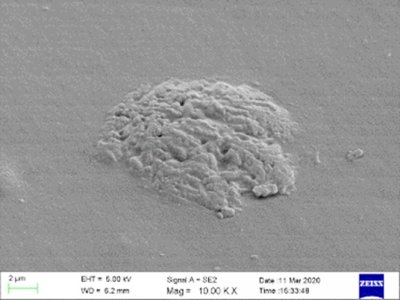

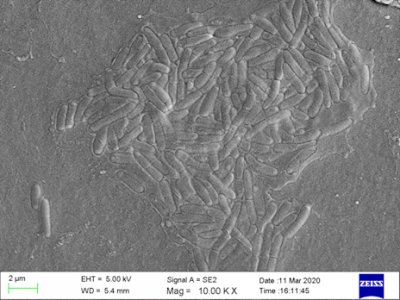

Surface Modification of Silicone Catheter for Prevention of Bacterial Adhesion: Under a project on “surface modification of silicone catheters for prevention of bacterial adhesion as well as biofilm formation”, a set of preliminary experiments have been conducted. It has been observed that plasma surface activation process results in physico-chemical changes on the silicone catheter surface which comprises of attachment of oxygen containing functional groups and generation of nano-scale roughness. Because of this surface, free energy increases significantly. In 6 days of aging study, polar part of the total surface energy decays and reaches the value comparable to the control sample whereas dispersive part does not change much in aging duration. therby establishing that plasma induced physico-chemical changes cause reduction of bacterial adhesion and growth on the catheter surface.

(a)

|  (b)

|

Biofilm formation (a) growth of bacterial cells (b)on untreated silicone catheter surface (c) Plasma treated silicone catheter surface with (d) very less bacterial adhesion and growth

| |

(c)

|  (d)

|

Plasma Thrusters

Thrusters are devices used to position satellites in orbits/outer space as well as for deep space propulsion. Plasma thrusters are one category of electric propulsion devices. The plasma discharges and the interaction of plasma with the dielectric materials play a vital role in the peformance of the plasma thrusters. IPR has been working on plasma thrusters in various areas such as basic sciences as well as in applied sciences in collaboration with ISRO.

Recent Developments:

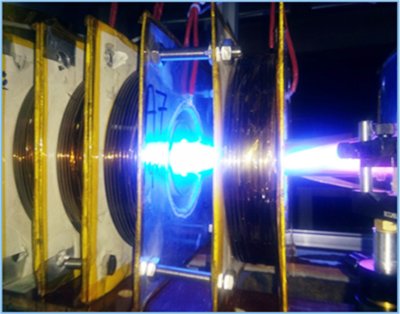

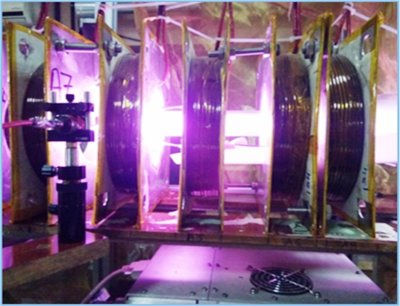

Helicon Plasma Thrusters: Helicon plasma thrusters hold the promise of higher specific impulse and long lifetime as compared to other types of thrusters for long-duration, low-thrust applications in space. Building on IPR’s basic research experience with helicon-wave driven plasmas, a lab-scale helicon plasma thruster system has been designed, fabricated and operationalised at IPR. A thrust of 10 mN has been achieved with 1500 W RF power, corresponding to a Spe-cific Impulse and Thrust efficiency of 250-500 seconds and 6% respectively. Further optimisation and thrust increase is expected in the coming months

|

|

|

Helicon Plasma Thruster experiments in Operation

- Plasma Surface Engineering Applications

- Atmospheric Plasma Applications

- Plasma Thrusters