6 IR Thermography

NDT Introduction:- Non Destructive Testing (NDT), Non Destructive Evaluation (NDE) and Non Destructive Inspection (NDI) are the terms used to represent the techniques that are based on the application of physical principles employed for the purpose of determining the characteristics of materials or components and for detecting and assessing the inhomogeneities defects without destructing such materials or components.

IR Thermography

Contact: Mr.Kedar Bhope

(kedar AT ipr.res.in)

Ph.No: +91-79-2396 4156

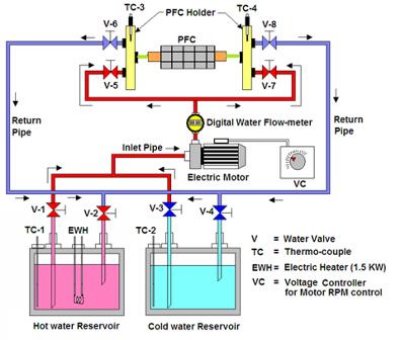

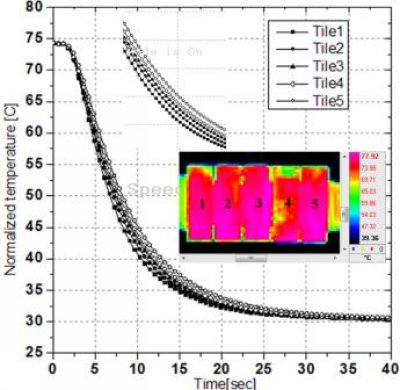

Transient Infrared (IR) thermography is one of the non-destructive techniques, which is used for quality control of plasma facing components (PFCs). Transient Infrared thermography set-up has been developed specially for testing the macro-brush, monoblock type PFC mock-ups. It consists of hot & cold water loop (as shown in figure*) and FLIR IR Camera SC5200M. The heat sink of the mock-up (Tungsten/Graphite) was connected the water loop system. The water loop was connoted to a cold water supply (that is at room temperature) and hot water supply (80 C). Temperature of water is measured using thermometers (Measurement range 20 C to 200 C). An IR camera is used to scan the surface temperature of the mock-up at 50 Hz full frame rate. The defect present at joint and inside mock-up has reflects in surface temperature of mock-up monitored by IR Camera. IR film generated by IR camera further processed using Image Processing tool box of MATLAB.